GTM Frame & Chassis

The GTM Frame & Chassis

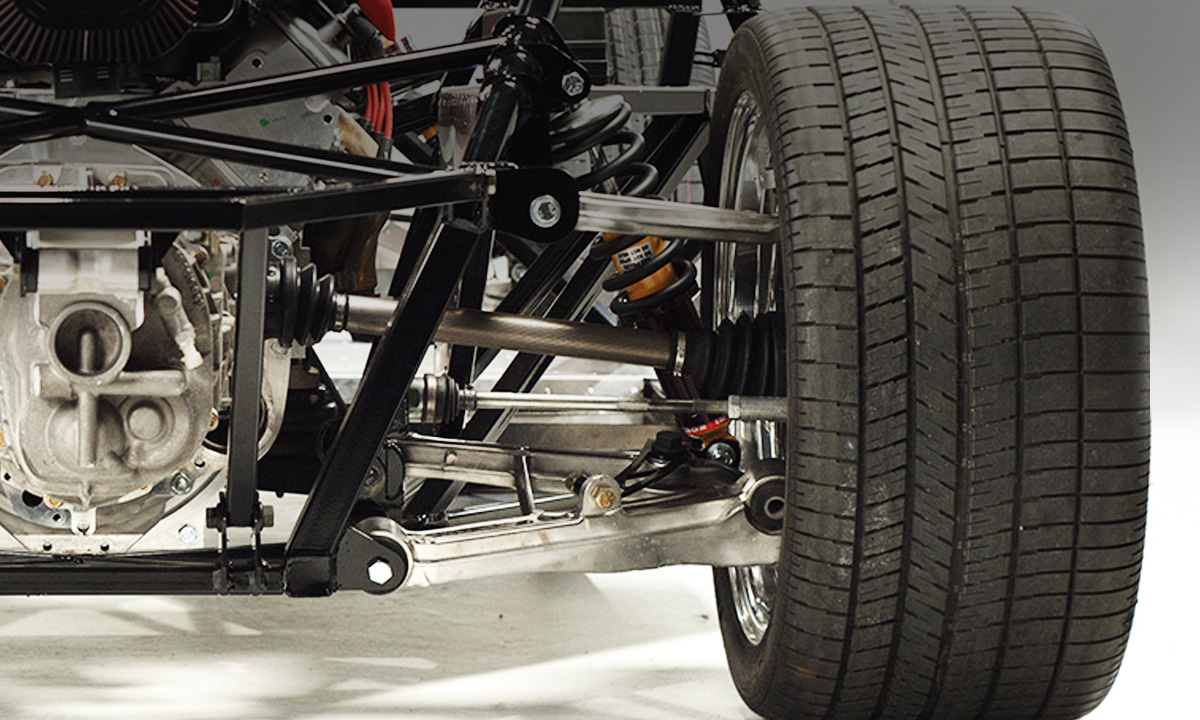

The Factory Five GTM uses an ultra-strong space frame and is joined by a matrix of aluminum sub-frame panels to complete a true race-car construction. Built on the strong foundation of this tough chassis is a four corner coil-over shock suspension with unequal length control arms and massive Corvette brakes. The composite body rests on top of this chassis and is a separate unstressed assembly.

The performance and success of the GTM is dependant first and foremost on the quality and strength of the frame. When the editor of Car and Driver magazine, Larry Webster, commented that the car handled the monster LS7 power “better than the Z06 Corvette”, it was due primarily to the design and strength of the space frame. Our engineering team spent over five years and countless hours on the computer and at the track to make sure the frame is stronger and more rigid than you’ll ever need.

The performance and success of the GTM is dependant first and foremost on the quality and strength of the frame. When the editor of Car and Driver magazine, Larry Webster, commented that the car handled the monster LS7 power “better than the Z06 Corvette”, it was due primarily to the design and strength of the space frame.

A Great Car Starts with a Great Chassis.

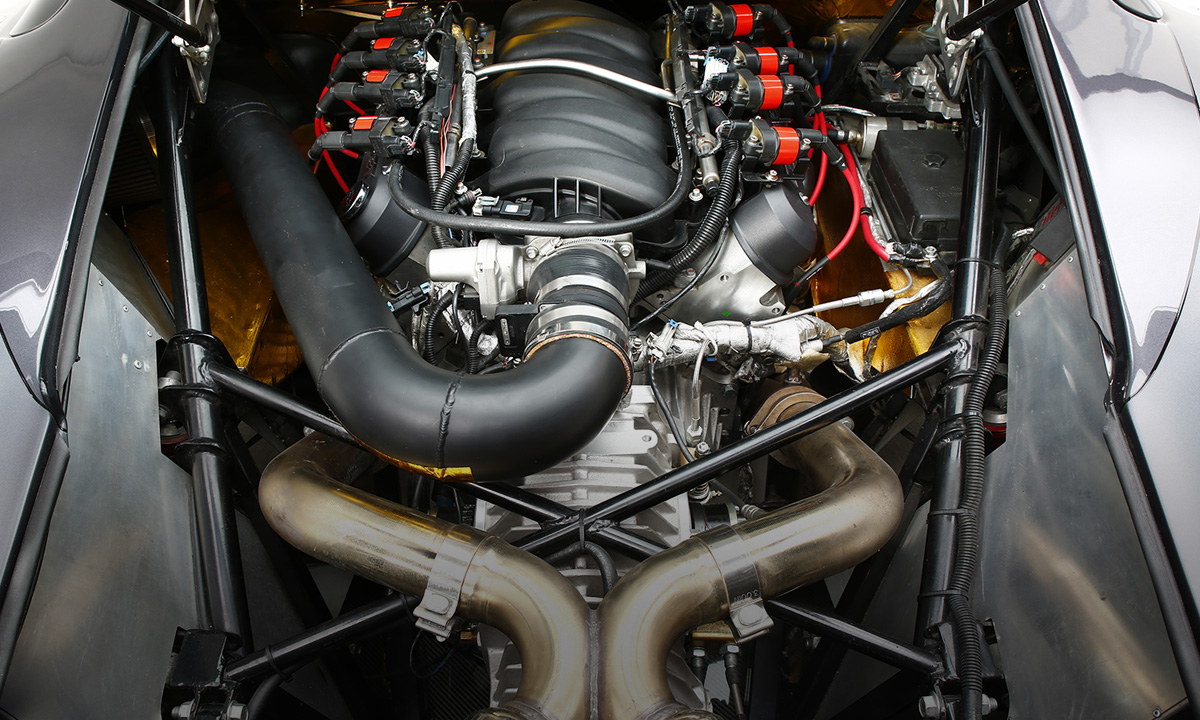

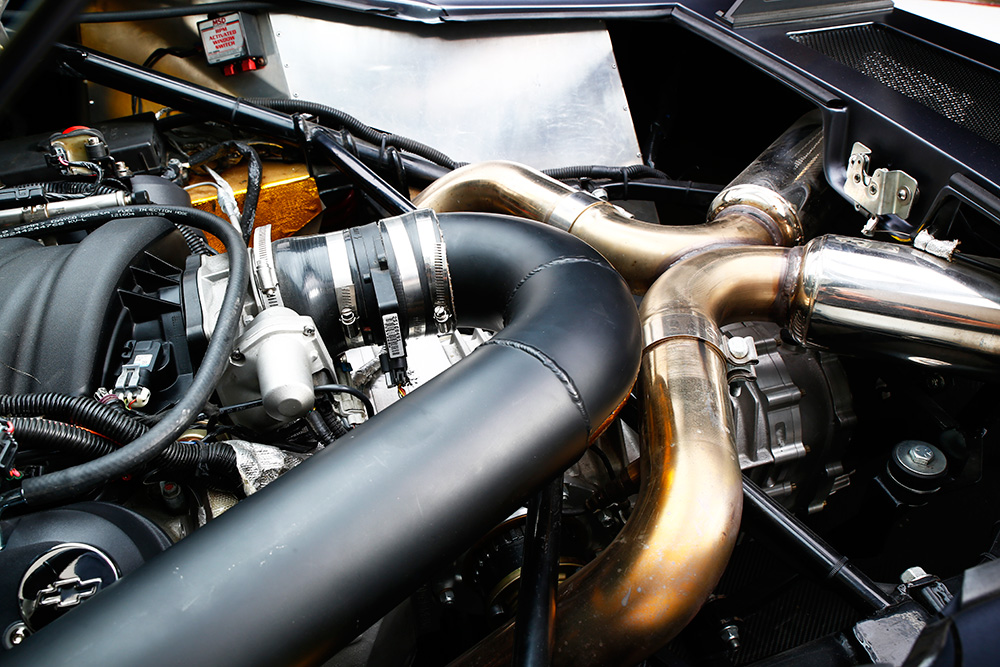

At the very core of the GTM Supercar is a computer designed, ultra-rigid space-frame. The frame is made of mig-welded, high strength 1020 and mild carbon steel tubing and plate steel. This special design incorporates a low center of gravity, high torsional rigidity, and solid safety features that delivers true Supercar performance in a safe and secure vehicle design.

- Solidworks® CAD designed frame with low center of gravity with high strength.

- Surface finish is powder-coated in beautiful gloss black finish

- Manufactured on a computer designed frame jig with 0.02”tolerances and made from high quality DOM tubing.

- Integral 6 point roll cage with roof-contoured bars for additional headroom in cockpit

- Safety designed collapsible steering column design and mounts

- Safety designed side impact bars, footbox protection and front/rear crumple zones.

- Twin fuel cell location centralized in chassis (similar to corvette design) aides in impact protection.

- Bolt-on rear transmission mount makes install and replacements easy

- Steel floor pans and sheeted flat bottom design aides aero/downforce and improves safety.

- Welded mount plates “ready-to-bolt-on” for engine, transmission, pedal box, radiator, steering gear, suspension, and shift linkages.

- Hood, doors, and rear hatch mount to frame, not body shell.

- Frame design allows for ultra-low engine placement for low vehicle center of gravity.

- Mid-engine design has good weight distribution, but even better mass centralization (heavy parts of vehicle towards center).

Our welded parts are made in the USA with American labor.

Our welded parts are made in the USA with American labor.

The Factory Five Mk4 frame is computer designed on Solidworks™ software using Hewlett Packard workstations.

The Factory Five Mk4 frame is computer designed on Solidworks™ software using Hewlett Packard workstations.

GTM Running Gear

GTM Running Gear

A famous person once wrote that a man has got to know his limitations. So does a company. Factory Five’s success over the years has been due to understanding what we can do and what we can’t. While the CAD/CAM revolution has indeed made it possible for small, technically proficient design and engineering companies to do great things, it hasn’t changed the reality that only a company with massive resources like GM can design complex mechanical systems.

A famous person once wrote that a man has got to know his limitations. So does a company. Factory Five’s success over the years has been due to understanding what we can do and what we can’t. While the CAD/CAM revolution has indeed made it possible for small, technically proficient design and engineering companies to do great things, it hasn’t changed the reality that only a company with massive resources like GM can design complex mechanical systems.

That’s why our team relies upon the proven running gear from GM’s World-class Corvette and Corvette Z-06. Major complex assemblies include Engine, Computer engine controls, fuel system, and front and rear suspension/braking.

The GTM is designed to accept GM LS series engines. From the proven 350 HP LS1 to the potent 430 HP LS3s and 500+ HP LS7s.

GTM Composite Body

GTM Supercar Body/Exterior

Performance Automotive Art. The GTM has pure supercar lines. Low, menacing and powerful... those are the words that come to mind when one sees the GTM in person for the first time. But looks have to support function. No matter how fast a sports car is, it has to look good. That's why we developed this shape in the wind tunnel and at speed on countless racetracks over a process of five years.

We know molding. Since 1995, we’ve built and shipped more than 11,000 body shells and over 40,000 body panels, and built more than 100 complex molds and tools.

![]() “Station to station at Factory Five, it is clear that quality principles are in full force.”

“Station to station at Factory Five, it is clear that quality principles are in full force.”

Craig Fitzgerald | Editor, Hemmings Muscle Machines

GTM Suspension & Brakes

GTM Suspension & Brakes

We’ve already proven the GTM suspension in conditions more demanding than you ever will. We’ve competed in the 25 Hours of Thunderhill for more than five years. The GTM was developed and tested on the racetrack, at the dragstrip, at autocrosses, and ultimately in the real world out on the streets.

The complement to a lightweight and rigid chassis is a well developed suspension. Our engineering team applied the lessons they learned developing and racing in the Factory Five Challenge Series to design a world-class suspension for the GTM.

We selected the tough and lightweight aluminum Corvette control arms and matched them to proprietary frequency selective dampening coil-over shocks and springs developed with the team at KONI Shocks. The FSD KONIs deliver razor sharp handling at modest speeds, while maintaining Supercar manners at Supercar pace.

GTM Interior

GTM Interior

The GTM kit comes with a complete interior including, sport seats, carpeting, headliner, roll cage covers, covered interior panels, door panels, engine cover, rear bulkhead, dash assembly, carbon fiber dash face, complete gauge set, and directional vents for heating and cooling. Covered interior pieces contrast with the carbon fiber gauge pod and functionally elegant layout of the interior.

Everyone asks, “Do I fit?” For a car that is only 42” high, the cockpit space is remarkable. Sitting in the car you’ll find a large and quiet cockpit with good front and rear visibility and modern temperature controls. Following a careful entry and exit, you’ll find head-room, legroom and front/rear visibility that is surprisingly well executed. An elegant and simple interior focuses the driver on the serious job at hand.

"...if you even look at the gas pedal, it will flatten your face in an instant."

Rob Kinnan, Former Editor Hot Rod Magazine

GTM Specifications

GTM Specifications

Engine, Chevrolet LS7

Configuration: Pushrod 16v V-8 aluminum block and heads

Displacement: 427 CID / 7011 cc

Maximum Horsepower: 505 at 6200 rpm

Maximum Torque: 475 at 4800 rpm

Redline: 7000 rpm

Drivetrain

Transmission: 6 speed manual

Final drive ratio: 3.44:1 limited slip

Clutch: 9.5 in. single disc

Suspension

Front suspension type: Independent double arm

Rear suspension type: Independent double arm

Shock-Springs: KONI coil overs

Steering Rack and pinion: 3.25 turns lock- lock

Brakes: Vented 13 in. front discs, Vented 12 in. rear discs

Wheels: 18” x 9” front 18” x 12” rear forged aluminum

Tires: Front - Toyo Proxes 245/40/18, Rear - Toyo Proxes 335/30/18

Vehicle

Weight: 2435 lbs.

Weight Distribution F/R: 40.1/59.9 (Percent)

Wheelbase: 101 in.

Overall length: 171.5 in.

Front Track: 60.5 in.

Rear Track: 62.0 in.

Overall height: 42.5 in.

Overall width: 74 in.

Ground clearance: 4.25 in.

Fuel Capacity: 18 Gallons

Construction

Layout: Mid engine RWD Coupe

Frame: Tubular space frame

Roll cage: Frame integral 6 point roll cage

Sub-structure: Aluminum paneling riveted and bonded to frame

Restraint System: Manual 3-point belts