30 days ago, we decided to try and build an 818R and make it to the Ultimate Track Car Challenge (which is held a week from today, July 18th). This is part of a pilot episode of a potential reality TV show. I thought it might be a little bit of manufactured drama, but now 25 days into the project, it is definitely a pretty significant challenge that we decided to take on. The good news is that the engineering team has done a great job in taking our 818R benchmark and going to the next level with logical changes. We will summarize the things we did to the car to make it faster when we get home from the track the week after next. Here are some photos of the project just for fun. Full details will follow as we really don’t have time to communicate most of this work.

The project is to take the set-up from the already fast 818R (blue car above) and make it even faster with an all-new 818R build.

We thought for a few seconds of cannibalizing the 818S for parts when the STi block we were using was found out to be junk, but the car was just too pretty and we found another mill.

170,000 mile Subaru donor car started the project. We bought the car from Christian at High Octane Images (sorry Christian, we didn’t want you to see your baby gutted).

The new car chassis and body was rolled into R&D.

Parts from the demo rolling chassis were used.

Jesper installs Wilwoods smaller (and lighter) disc brake kit.

The STi block was torn down and upgraded. Turbos were ordered, the transmission was sent out to be upgraded.

We decided to try a red gel-coated body because we didn’t have time to paint the car and we are considering offering different color gel-coats.

Body fitment was actually pretty fast. We are using a white deck and white hood to replicate the paint scheme of the blue 818R, but in red and white.

A lot of suppliers have helped with parts. KONI, Wilwood, Electromotive, etc. APR sent us their latest road race wing that promises to deliver a tremendous amount of rear downforce. Picture above shows our custom positioning jig for the frame mounts (that’s a joke).

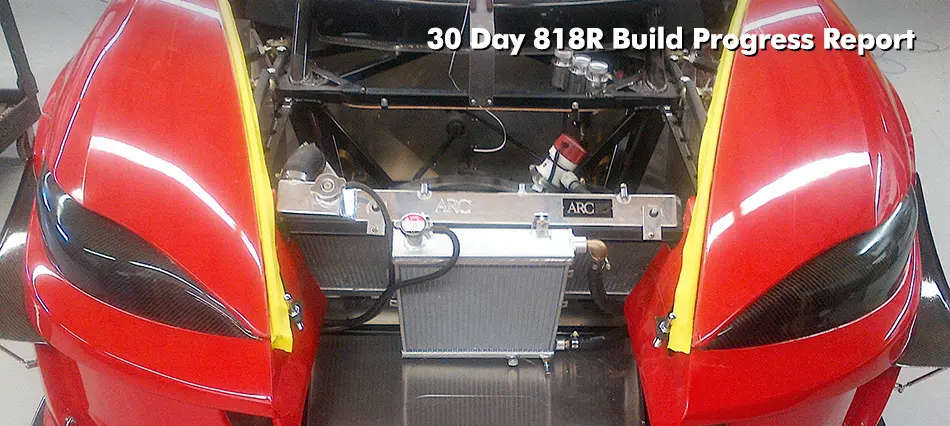

The turbo runs with a bigger intercooler and heat exchanger. Front headlights are replaced with blockout panels and we are adding front canards for more front downforce.

John helps fit panels while the engine goes together.

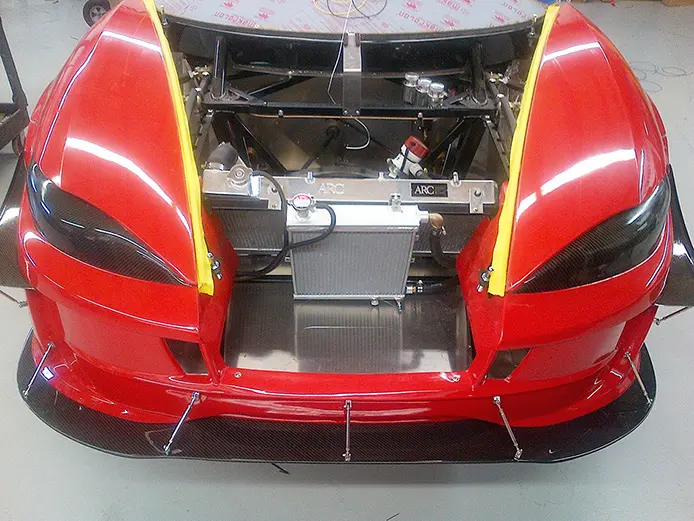

Tony Zullo finishes the front end. Note the front splitter is a bit further out.

Dan helps with wiring.

This picture is from Thursday evening with only four before the first track test scheduled for Tuesday and UTCC is on Friday.

The front end is mostly done (above) and Jim works on wiring (below).

Next week, the team will be on the road with the car and I will report from VIR on the status if the team doesn’t kill me before then.

Update, Sunday July 13: The guys worked through the weekend and completed the red 818R. This week, we have a few days to do some shake down testing and driving before heading to VIR for the Ultimate Track Car Challenge on Friday, July 18th.

We didn’t have time to paint the car, so we used the opportunity to test gel coat color in red. The blue car was painted and the red car here is red and white gel coat. Tony buffed the red gel coat and didn’t have time to touch the white gel coat, but everyone agreed they look pretty darn good.

Update, Wednesday July 16:

We ran Lime Rock yesterday to test and tune. Its a good thing we did as we had a stuck master cylinder which completely melted the front brake caliper pistons. The boys at Wilwood are FedExing us new front brakes since we are heading today for Virginia. We did manage to run a 56.3 seconds lap time which is pretty darn fast on an old set of slicks (we’re saving the new ones for UTCC). Didn’t have enough time to optimize downforce as we had some cooling issues. The crew has been working on the cars all morning and we are loading up shortly.

Here’s what happens where your brakes don’t let go and you keep racing.

Both 818Rs are about to be loaded on the trailers even though it doesn’t look like it. The red car is testing a recessed door cut-out (that’s the black area on the leading edge of the door). We probably will not be able to get to the wind tunnel on this trip, but this part and the new wings/canards really need it

John George will be driving and he is bringing his tech gear.

Last challenge on the list seems to be getting the alternator working. A new one is minutes away.

Dave Smith

President